Nate Hoffman, one of my mentors at my first job, supported the #DOE and NASA Glenn Research Center #GEVALTIG concept study in the late 1980’s when he worked at the Energy Technology Engineering Center ( #ETEC), which was run by the #Rocketdyne division of Rockwell International (now Aerojet Rocketdyne). When Nate talked about this at lunch in the cafeteria, he was excited to relive past glories that he was able to work on a concept that used a 6 MW #fission #reactor to power a #fusion reactor, that the system used #superconductivity, and that fancy technology like #heat pipes, #lasers, #tritium, and #electromagnetic pumps were baselined. Compare that to the #Dragonfly mission that will take 8 years to send a 452 kg rotorcraft to reach Titan using current technologies.

Imagine being able to go on a round trip to Saturn’s moon #Titan in 500 days on a #inertial #fusion powered #spaceship weighing 16,000 to 20,000 tons in orbit. #departmentofenergy #nuclear #isotopes #Pu238 #radioactive #ORANO #INL #ATR #ORNL #REDC #NASA #spaceexploration #transportation #engineeringīRR Cask Use for Pu-238 Isotope Production If you’re interested in how the BRR was qualified to move Pu-238 heat source feedstock that will help power Radioisotope Thermoelectric Generators (RTG) for #future deep #space #NASA missions, check it out in the link below. Phil Noss from ORANO FEDERAL SERVICES LLC worked with Austen Fradeneck, Ryan Marlow, Andrew Zillmer, and Richard Howard to prepare a paper for the recent #PATRAM conference to give an overview of how the BRR cask was licensed to transport material for Pu-238 between #INL and #ORNL.

Once you’ve made an #isotope, you need to get it to where it will be used or an end customer. But how do you actually do you actually ship it? If the material isn’t very #radioactive, you could use a Type A container, which ranges from a fancy cardboard box to something that looks a little like a can of food to a small cask. For more radioactive material, you will need to use a Type B container, which can range from a small container to a cask weighing more than 100 tons.įor production of #Pu-238 at Idaho National Laboratory, we will use a BEA Research Reactor ( #BRR) cask to move irradiated Pu-238 production targets from the Advanced Test Reactor ( #ATR) to the #Radioisotope #Engineering Development Center ( #REDC) at Oak Ridge National Laboratory for processing. #spacenuclear #requirements #systemsengineering #SNAP10A #reactor #telemetry #AtomicsInternational #AerojetRocketdyne #Atlas #NASA #AEC

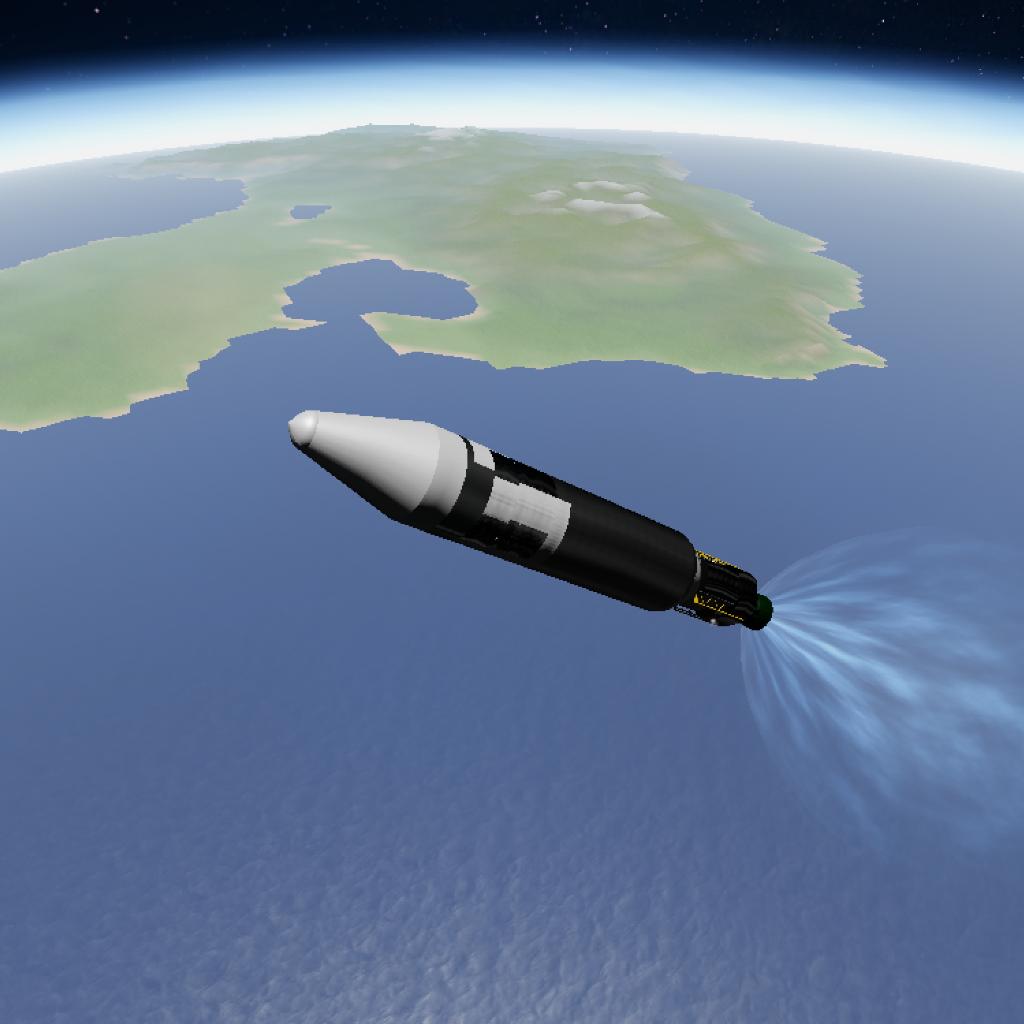

Atlas agena payloaf full#

Imagine it’s a few years from now, and you have a #space #reactor that is integrated into the #payload faring and is sitting on the pad. You’re sitting in #mission control, and you get asked to look at some odd signals from some of the #instrumentation. It looks like you are having some dropouts and off-scale readings on multiple I&C channels. The #telemetry launch #requirements call for readings from most of the sensors or the launch will be scrubbed and the reactor and #spacecraft de-mated from the payload faring and have trouble shooting performed. After some trouble shooting, there was a poor connection on some cabling and the mission met it’s go/no-go launch requirements.Īfter the launch, you think back about the requirements that you developed, and wonder if maybe they were too strict. But where would you find something to compare your requirements to a historical launch. Turns out, the SNAP 10A reactor built by Atomics International (now Aerojet Rocketdyne) on the #SNAPSHOT mission that was launched on an #Atlas Agena D in April 1965 gives some insight into reactor launch requirements. As the table below shows, there weren’t many indicators needed for a ‘go’ for launch, and once the spacecraft got to orbit there was significant #redundancy in instrumentation to enable #startup and full #power operation.

0 kommentar(er)

0 kommentar(er)